Brushless Tools vs Brushed Tools: Which Power Tool Is Better for You?

What's the difference between a brushed and brushless tools? We break down the pros and cons of both power tools, so you can choose the best fit for your needs.

By:

The Good Home Daily

Posted on August 22, 2025

More and more people are switching to brushless power tools these days. Tools powered by brushless motors are said to offer longer life, less maintenance, and better performance. They have become the new benchmark for professionals and serious hobbyists alike.

According to Global Market Insights, the brushless motor segment accounted for over 39% of the cordless power tools market in 2024.

But if you have been using brushed tools for years, it is fair to ask: what is the real difference, and are brushless tools really better?

Before you decide on your next upgrade, we will explain what brushless tools are, how they work, and how they compare to their brushed tool counterparts.

First, What Are Brushed Power Tools?

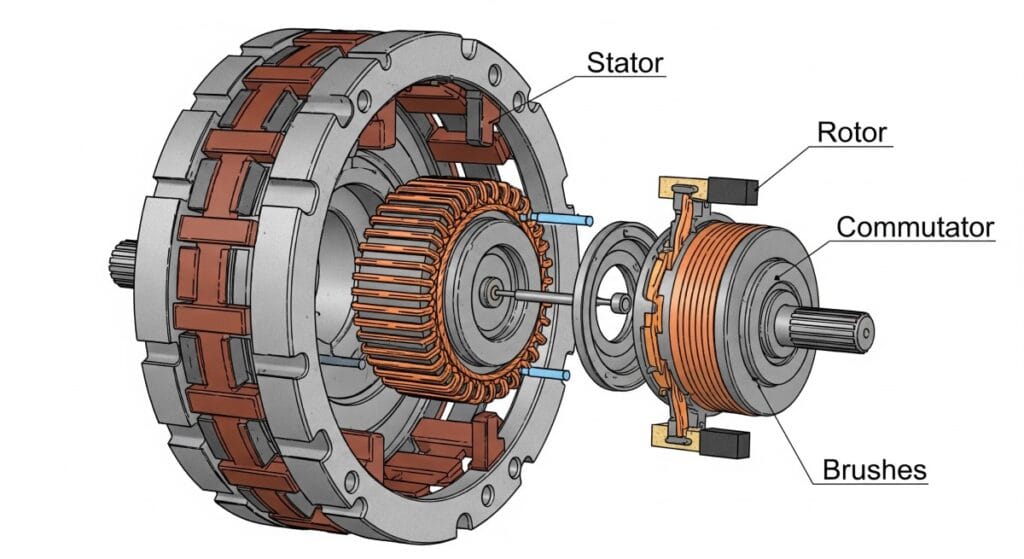

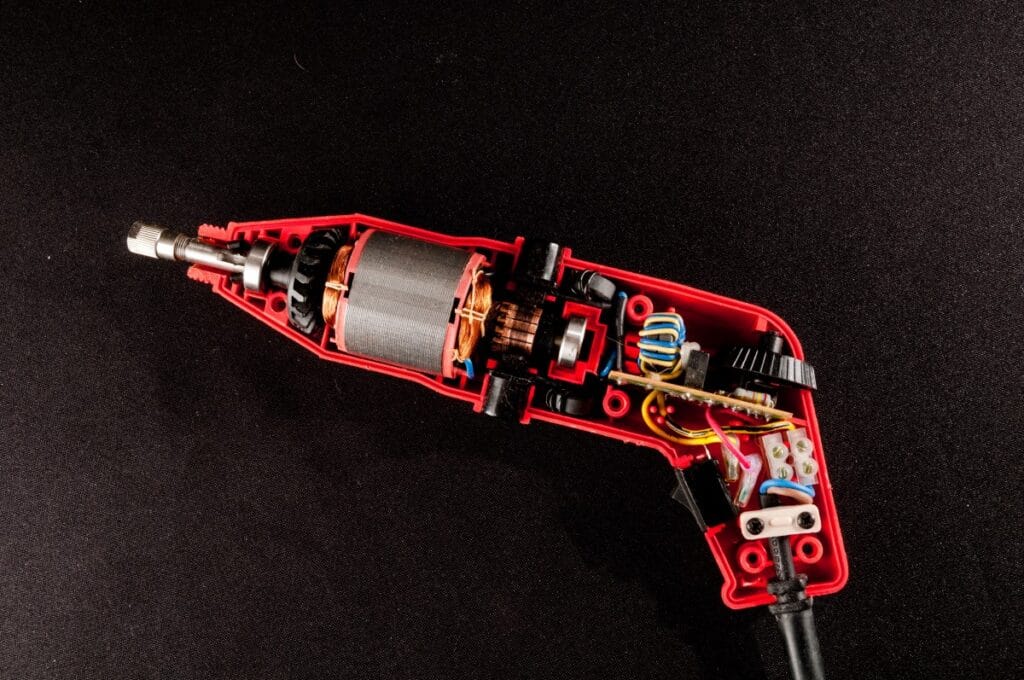

As the name suggests, brushed tools use brushed motors, a type of DC motor that has been around for decades and is still common in many power tools today. At the heart of these motors are carbon brushes. These brushes are small blocks of carbon or graphite that rest in brush holders inside the motor housing.

The brushes have one main job: to deliver electricity from the power source to the motor’s spinning section through the commutator. They constantly transfer electrical energy to keep the motor turning.

The commutator then directs the current into the armature, which is made of tightly wound copper wire wrapped around an iron core. When energized, these windings become electromagnets. Their magnetic force pushes against the stationary magnetic field of the stator, and this push is what makes the rotor spin.

But there’s a catch. For the motor to keep spinning, the brushes must constantly rub against the commutator. This is the very same friction that creates heat and causes the brushes to wear down over time.

What Are Brushless Power Tools?

A brushless motor isn’t exactly a new technology. Its roots go back to the 1960s, when T. G. Wilson and P. H. Trickey introduced what they called a “DC motor with solid-state commutation.” However, this technology wasn’t intended for power tools but for industrial and aerospace applications.

Makita was the first to bring the brushless motor to power tools in 2009 with its 18V LXT brushless impact driver, after initially developing the tech for defense and aerospace in 2004.

Other global brands, like Bosch, followed with their own high-performance brushless lines such as BITURBO. In the Philippines, local brand Lotus Tools Philippines now offers affordable brushless drills, impact wrenches, and grinders.

So, what does brushless mean in power tools, and why is it getting so much attention?

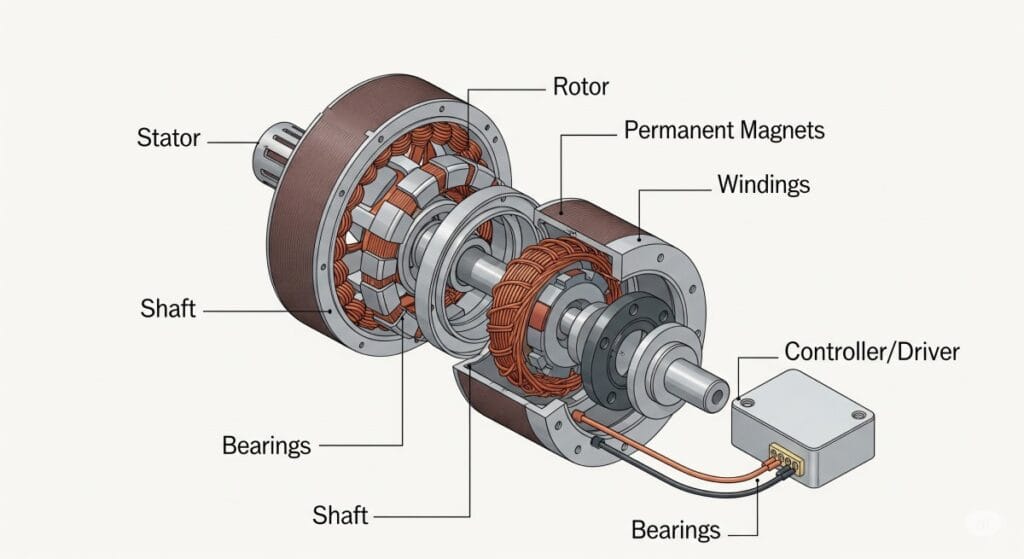

Put simply, it is a motor that works without carbon brushes. Instead of relying on physical contact to deliver electricity, it uses an electronic controller to manage the whole process.

To compare, in a brushed motor, carbon brushes press against a spinning commutator to send power into the rotor windings. That constant contact creates friction, heat, and sparks, which is why brushed motors wear down over time.

With a brushless motor, things work differently. The windings stay fixed in the stator, while the rotor carries strong permanent magnets. An electronic controller acts like the motor’s brain, sending timed bursts of electricity to the windings. This creates a shifting magnetic field that pushes and pulls on the rotor magnets, making it spin.

The best part is that the controller can sense how much work the tool needs to do and adjust power on the fly.

For example, when cutting thin plywood, a brushless circular saw will run lightly because it detects low resistance. However, when cutting a dense hardwood, it automatically delivers the extra torque power through. This results in longer runtime, less heat buildup, and greater efficiency compared to brushed motors.

Brushless vs Brushed Tools: Side-by-Side Comparison

When comparing brushless tools and brushed tools, the differences go far beyond the presence or absence of carbon brushes. Below is a table is a closer look at each key aspect:

Comparison Points

Brushless Tools

Brushed Tools

Lifespan

Longer due to less wear on parts

Shorter because brushes wear out

Maintenance

Minimal, no brushes to replace

Requires brush replacement

Noise

Quieter Operation

Louder due to brush contact

Heat

Runs cooler

Generates more heat

Performance

More Efficient and Consistent

Less Efficient, Power drops as brushes wear

Cost

Higher upfront price

Lower initial cost

Lifespan

The durability of a brushed motor is limited by its design. The carbon brushes wear down over time, and they eventually need to be replaced. This is often the primary point of failure for the tool.

A brushless motor has a significantly longer lifespan because it has no brushes to wear out. The absence of friction and heat means the motor runs cooler, putting less stress on all the internal components and making for a much more reliable tool over many years of use.

Maintenance

A brushed tool requires maintenance. The carbon brushes will need to be inspected and replaced periodically, which can be a hassle and an added cost. A brushless tool is virtually maintenance-free. With no brushes to wear down, the motor is sealed and designed to last the entire life of the tool without any internal service.

Heat Production

A brushless motor converts more electrical energy into mechanical power with minimal loss, so it runs cooler even during demanding tasks. The lack of friction from brushes means less heat buildup, which also helps extend the motor’s lifespan.

Brushed motors create more heat because of the constant friction between brushes and the commutator. Over time, this extra heat can cause wear on components and, in extreme cases, lead to sparks and reduced efficiency.

Performance

The biggest difference between these two motors is in power delivery. Brushed motors use physical brushes, and that friction wastes energy as heat. This results in less consistent power and a shorter battery life.

Brushless motors use a smart electronic controller to manage power with no friction at all. This makes them up to 50% more efficient, giving you longer runtimes and more consistent power under heavy loads.

Cost

Brushless tools typically cost more upfront due to their advanced design, electronic components, and longer lifespan. However, the reduced maintenance needs and improved efficiency can make them a more cost-effective choice in the long run.

Brushed tools are less expensive to purchase and can be perfectly suitable for occasional use, but over time, the cost of replacement brushes and potential repairs can narrow the price gap.

The Brushless Advantage

Now that we have compared brushless tools and brushed tools side by side, it is clear why many professionals prefer going brushless. Brushless wins in lifespan, maintenance, heat production, and performance. The only edge brushed tools hold is on initial cost.

Brushless tools last longer since there are no carbon brushes to wear out, and they need less maintenance. The built-in electronic controller delivers consistent torque and speed, adjusting power as needed for each task. They are more energy-efficient, which helps extend battery life in cordless models, and they run cooler and quieter for a more comfortable user experience.

But, Are Brushless Tools Worth the Extra Cost?

One advantage brushed tools still hold is their lower upfront price. For homeowners who need tools for quick fixes or occasional DIY projects, a reliable brushed model can still get the job done without the bigger investment.

That said, for professionals or frequent users, brushless tools often prove worth the price. The longer lifespan, reduced maintenance, and improved energy efficiency can make them more cost-effective over time, especially for cordless tools where extended battery life is a big advantage.

The decision comes down to how often you use your tools, the demands of your projects, and whether you value long-term durability over initial savings.